Ningbo Detection Equipment LTD. is one of the earlier professional eddy current flaw detector manufacturers in China. Our company was founded in 1982. Our company has a strong technical force and a technical team full of vitality. We have established the concept of “challenging ourselves and pursuing excellence” and “positive, progressive, and innovative” as the spirit of our company. The detecting apparatus and equipment that we produce are sold throughout the country and in Hong Kong, Taiwan, the United States, Japan, India, etc. They are used in aviation, electric power, chemicals, metallurgy, iron and steel, machinery, oil, automobile manufacturing, bearings, mechanical parts, shipbuilding and Power Company, Steel Institute, tertiary institutions, and other fields

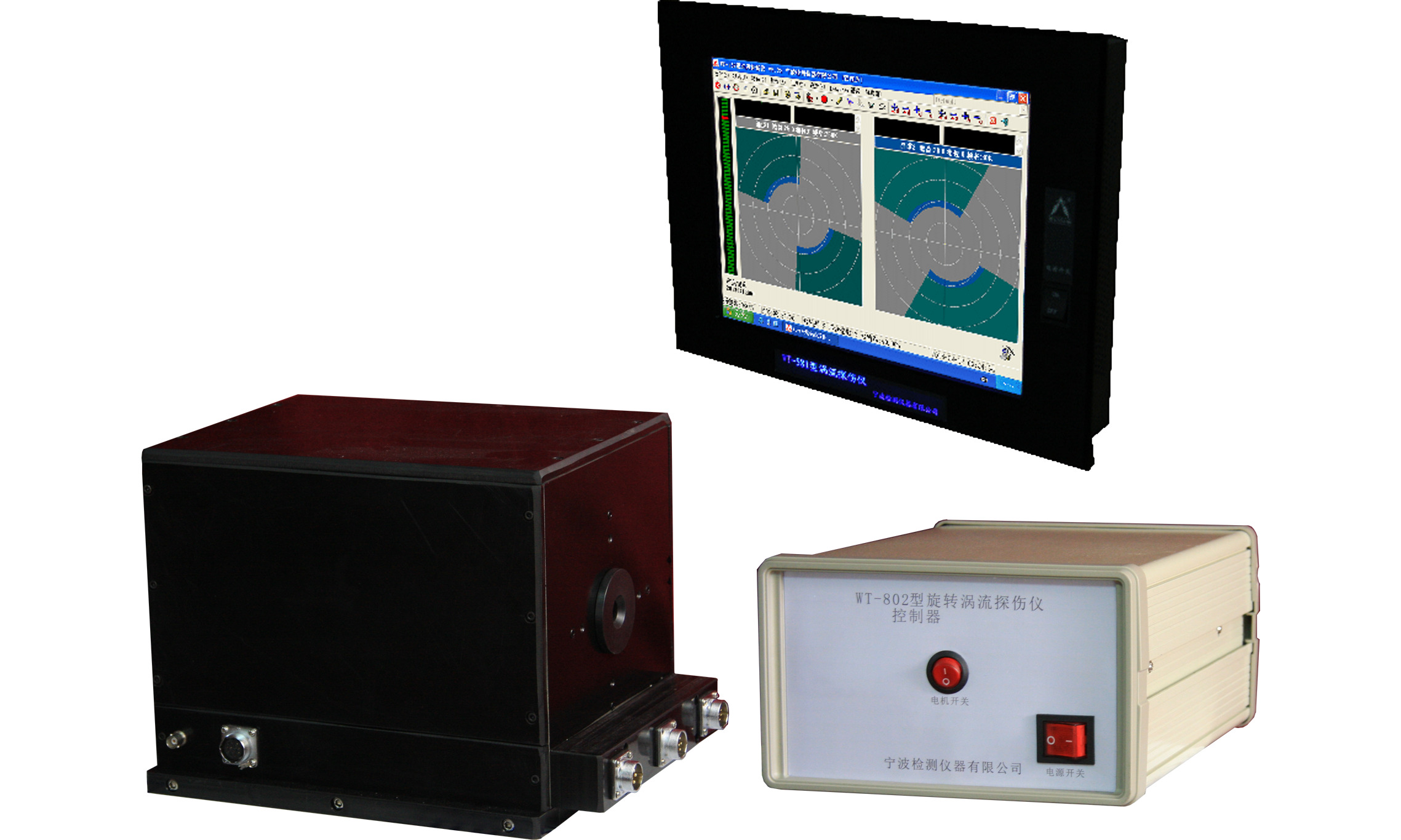

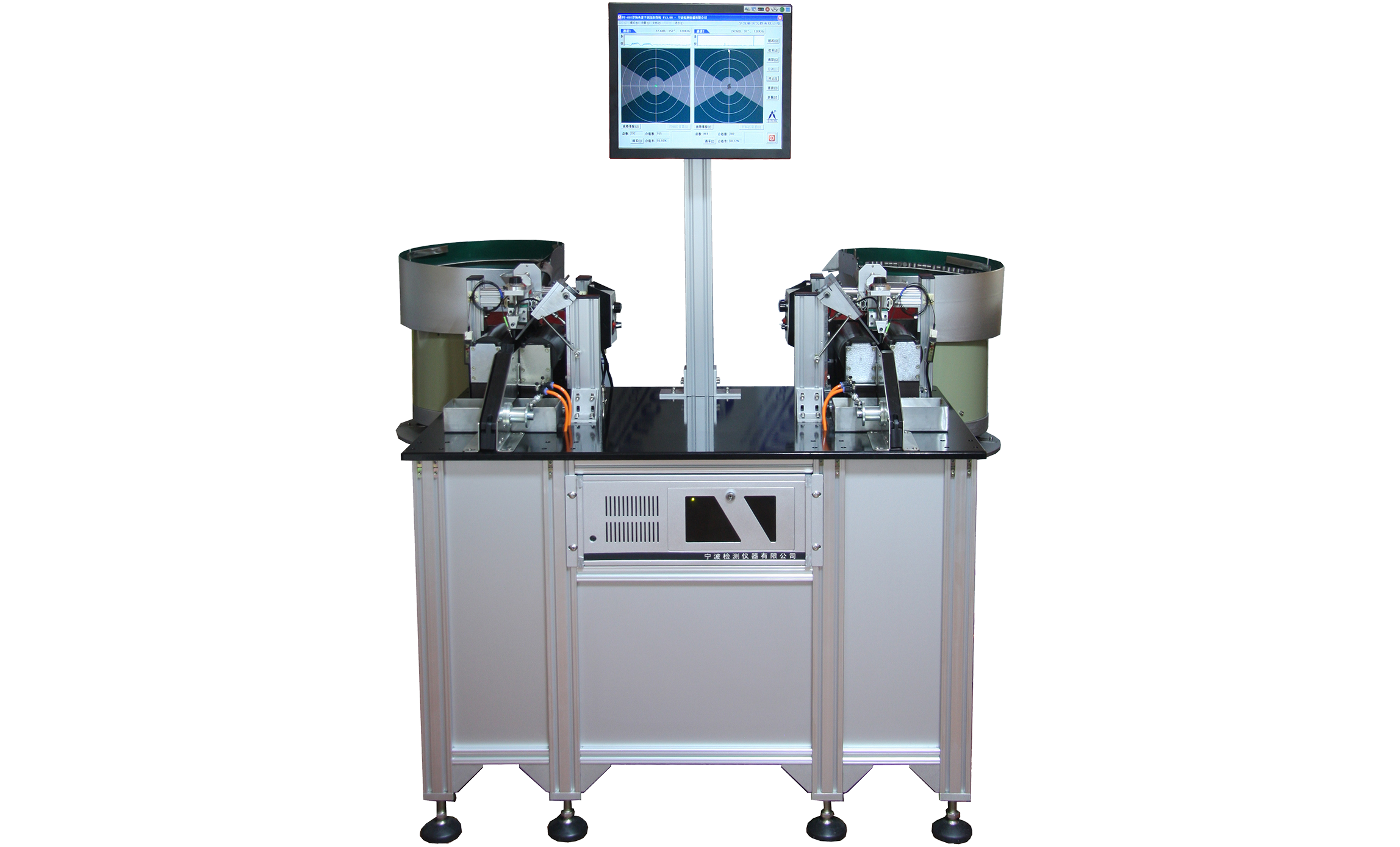

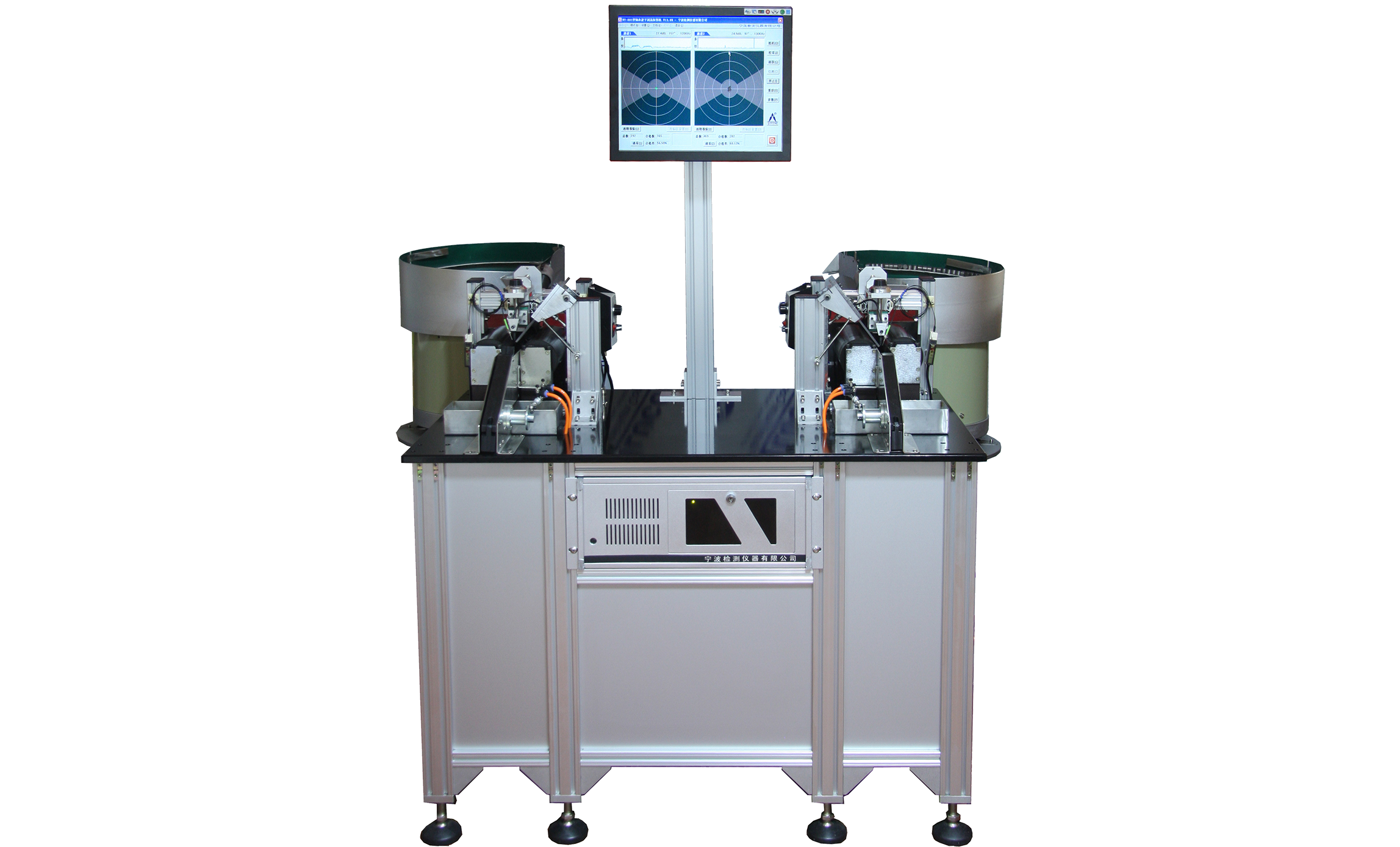

Our company focuses on produce research and development of innovative and forward-looking, equipment have been used in all kinds of metal pipe, bar, wire stock, wire material, profiles and metal parts of NDT. Such as: brass, titanium tube, stainless steel, aluminum-plastic, composite pipe, double-volume pipe, optical cable, wire, cable, roller bearings, bearing sets, Ball, bolts and other online and from the Line testing, the turbine shaft in the hole, the engine blades, pumping strength, drill pipe, such as testing. The automatic testing equipment, which designed by the need of mass workpieces online automatic testing in bearing manufacturing industries, is the only integration system with mechanical and electrical in one in china which has the most advanced eddy current technology and control by computer.

Company has an excellent quality assurance system and several decades of development, production experience. Absorb the best eddy current technology, and introduce of new international NDT standards Products closer to the user, sophisticated products to meet market demand and the needs of users, to satisfy customer